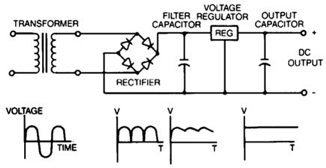

A power supply is a vital component of any machine. It enables functionality simply because most machine hardware requires power. Power supplies come in many shapes and sizes, but the most common one is an AC/DC converter. Current sourced from power plants or electric grids generally take the form of an alternating current (AC), while most machine hardware takes only direct current (DC). Converting AC to DC is the main function of a power supply, which is shown in the image below.

Of course, not all power supplies are made equal. They can vary considerably in quality. Load regulation, noise immunity, overvoltage protection, overload protection, and efficiency are just some specifications that affect the performance and quality of power supplies. You don’t want a faulty or low quality power supply; you want the highest quality power supply you can acquire.

When a power supply fails, it can break your entire system and damage other components, especially those that are highly sensitive. The consequences include premature failure or degraded performance, increasing your system’s overall losses. A low quality power supply can fail for a number of reasons, but most of the time it is due to the shortcomings of low quality components that can’t withstand the prolonged stress to which power supplies are subjected. But even high quality power supplies can fail. Most often, they fail for one of the following reasons:

- Broken multilayer ceramic capacitor (MLCC) components

- Long-mounting PCB screws

- Damaged ICs and FETs

- Careless soldering jobs and repairs

- Cracked PCBs

Each of these problems exists within the power supply, but there are also external factors. The environment, for example, is something that many designers overlook when choosing suitable power supplies. If your application is outdoors, your supply must be able to endure the environment. Whether it’s sunny or rainy, a good power supply must tolerate the weather and other outside influences. Specifically, consider the potential impact of temperature fluctuations, inclement weather, and insects, which, in combination, might cause high voltage and current surges, shorts, and other technical problems.

When choosing a suitable power supply, look for these five specifications:

- voltage and current specifications

- line and load regulation

- ripple, noise and temperature stability

- stability with time

- current limiting and overvoltage protection

An often overlooked specification in product selection is power quality, defined as how close to the ideal the power supplied to a load would be. Poor power quality can adversely affect your system by leading to higher energy costs, unstable equipment operation, and more frequent equipment failure. Incorporating all of these factors would help immensely in designing more stable and robust systems. Finding power supplies that fit all of these criteria may be made easier by finding a manufacturer that also considers these factors, which leads to superior quality and performance.

Camtec specializes in power supplies and specifically designs products to be robust and usable long term, even in outdoor environments, offering safety and reliability under extreme conditions like a harsh winter period. This is reflected in the products’ lifespan, which is 17-18 years, as compared to the average power supply lifespan, which is 5-10 years. Their product failure rate is 0.004% and they are used in traffic control systems, infrastructure and high-power LED lighting, railway, and even armed forces.

Camtec’s power supply standard products provide smooth capacitance-voltage (C/V) characteristics that enable starting even complex loads such as LED lighting, DC/DC-converters and series DC motor drives with naturally cooled AC/DC power supplies and switching mode power supplies. This allows their products to operate in the ambient temperature range of -20 ℃ to 70 ℃ when the usual temperature range is in 10 ℃ to 40 ℃. Camtec’s products are also highly efficient and meet the 90%+ Green Power Standard. So, whether it be inside or outside, Camtec has got you covered.

Why We Are One

For over 40 years, IBS Electronics Group has provided a broad range of integrated supply chain and electronicsmanufacturing solutions tailored specific to our customer's operations. As your one source for the industry’s top brands all in one place, our engineers specialize in reducing supply chain complexity and are here to provide you with dedicated support from prototype to production.

.png)

.png?resizemode=force&maxsidesize=96)