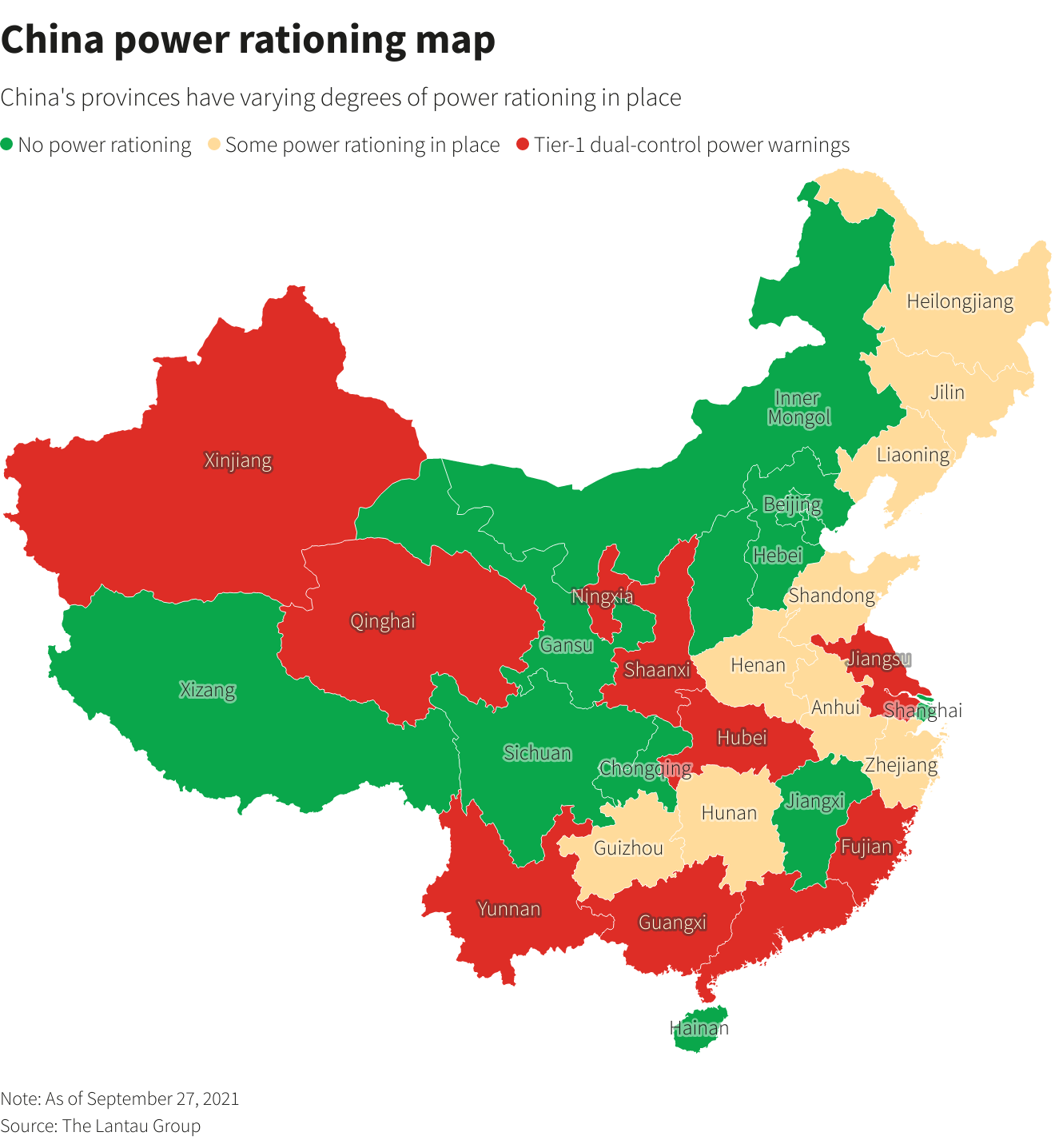

Across several Chinese provinces, there have been mandated power cuts to reduce energy consumption and CO2 emissions. China’s President, Xi Jinping, has committed to “not build a single new coal-fueled power plant going forward.” Around 65% of the electricity in China came from coal as of 2019, and recently the government of China has forced provinces cut their energy consumption.

Soaring energy prices and high demand has forced some factories in China to shut down, adding additional complexities for global supply chains as blackouts ripple across the country.

The power cuts and widespread blackouts have also slowed factory production as more regions of the world are reopening after pandemic-induced lockdowns, greatly increasing the demand for China’s export factories.

China power rationing map – Reuters Graphics

China power rationing map – Reuters Graphics

As electricity demand has soared, it has increased the price of coal to generate electricity, yet some Chinese regulators have not allowed utilities to raise rates to meet the rising costs of coal resulting in slow movement to operate their power plants for more hours causing more disruptions than anticipated.

According The New York Times interview with a local factory, “This year is the worst year since we opened the factory nearly 20 years ago,” said Jack Tang, the factory’s general manager.

In the city of Dongguan, a factory that employs 300 workers rented a generator for $10,000 a month to ensure production could continue. Considering the costs associated with the diesel fuel and the generators themselves, electricity costs have exceeded twice the cost for simply accessing the grid.

To help tackle this energy crisis, the National Development and Reform Commission announced on Tuesday plans to liberalize electricity pricing and abolish a power purchasing scheme that keeps costs artificially low for big users, according to the South China Morning Post.

With no certain end in sight, what does this mean for global supply chains and China export demands from the electronics manufacturing industry?

A number of chip enterprises in China have halted production temporarily, including the suppliers of semiconductors for foreign companies. CWTC, a semiconductor packaging material supplier for NXP and Infineon Technologies, previously released a notice saying that its factory in Suzhou, Jiangsu had suspended semiconductor production from September 26 to 30, in accordance with the local policy on power reduction.

ASE Kunshan, a semiconductor production company based in Kunshan, East China’s Jiangsu Province, said that the firm had received a notice from local authorities about power cuts from September 27 to 30 causing the factory to have no output during the period.

ESON, another chip production firm, said that its factory in Kunshan had halted production from September 26 to 30 due to the power cuts.

Many industry observers said the production suspension will escalate global chip shortages, further increasing chip prices.

Contact your IBS Electronics representative or click here to contact us for dedicated support to analyze how this will impact your supply chain. Our team will develop a bespoke solution to reduce complexities and mitigate production disruptions.

Why We Are One

For over 40 years, IBS Electronics Group has provided a broad range of integrated supply chain and electronicsmanufacturing solutions tailored specific to our customer's operations. As your one source for the industry’s top brands all in one place, our engineers specialize in reducing supply chain complexity and are here to provide you with dedicated support from prototype to production.

.png)

.png?resizemode=force&maxsidesize=96)